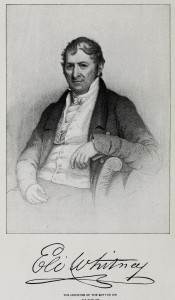

Profile of Eli Whitney – Inventor of the Cotton Gin

As the founder of the modern system of interchangeable manufacture of machinery parts which, at the present time, has a special significance in the competition for the world’ s market for engineering workshop products, Eli Whitney will always figure prominently in engineering history, though he is, perhaps, most widely and popularly known as the inventor of the cotton gin.

He was born at Westborough, Worcester County, Massachusetts, December 8, 1765, and gave indications of his mechanical genius at an early age. His father had a workshop with a variety of tools, which Eli learned to use while still very young. He was always making something in the shop, and much preferred this occupation to working on his father’s farm.

When he was fifteen or sixteen years of age he engaged in the manufacture of nails, which at that time were in great demand. With the aid of a few simple tools he carried on this occupation for two winters, and when, later, the business was no longer profitable, he turned his attention to making long pins for fastening on women’s bonnets, which were then in fashion, and also manufactured walking-sticks of peculiar neatness.

Even at the early age of fourteen he had acquired a large fund of general information and was particularly apt at figures and arithmetic, but as he grew older he felt the need of a more liberal education.

After overcoming many obstacles, he, therefore, entered Yale College, in May, 1789. During his college course he devoted more attention to mathematics and mechanics than to the ancient classics, and he also found opportunities to exercise his mechanical ingenuity.

Soon after taking his degree, in the autumn of 1792, he entered into an engagement to act as teacher in a Georgia family, intending to study law at the same time. But when he arrived at Savannah he found that another teacher had been employed in his place, and he was, therefore, glad to accept the hospitable offer of Mrs. Greene, the widow of General Nathaniel Greene, to make his home at her house while pursuing his legal studies.

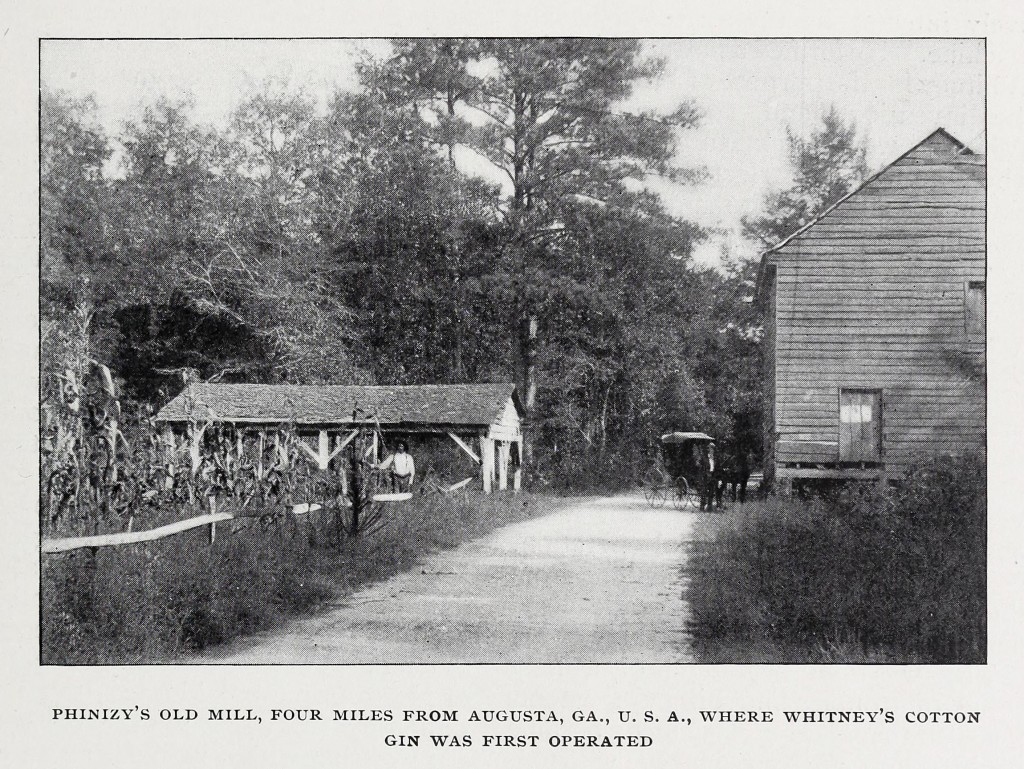

Not long afterwards, a large party of gentlemen, consisting principally of officers who had served under General Greene in the American Army, came from Augusta and the upland part of Georgia to visit Mrs. Greene and her family. In the course of conversation upon the state of agriculture among them, great regret was expressed that there was no economical means of separating the lint of the upland or green seed cotton from its seed, as much land which was unsuitable for the cultivation of rice would yield large crops of cotton. Separating one pound of the clean staple from the seed was a day’s work for a woman, and until some machine could be devised which would greatly facilitate the process of cleaning, it would not pay to raise cotton for the market.

While they were thus talking, Mrs. Greene recommended them to apply to her young friend, Mr. Whitney, who, she said, could make anything, in proof of which she showed them a frame for making embroidery, and a number of toys which he had lately constructed or repaired. She then introduced the gentlemen to Whitney himself, and though he modestly disclaimed the possession of any mechanical genius, their conversation made a deep impression upon him and gave a new turn to his thoughts. He got some cotton in the seed and began experiments in a machine for cleaning it, in a room of Mrs. Greene’s on a larger scale, but the extreme difficulty of procuring workmen and proper materials in Georgia prevented my completing the larger one until some time in April last. This, though much larger than my first attempt, is not above one- third as large as the machines may be made with convenience. The cylinder is only two feet two inches in length, and six inches in diameter. It is turned by hand, and requires the strength of one man to keep it in constant motion.”

Whitney’s machine, which became popularly known as the cotton gin, has house. He was greatly hampered by lack of proper materials and tools, but he set resolutely to work and continued at his self-appointed task all through the winter until his machine was so far completed as to leave no doubt of success.

In a letter, written November 24, 1793, to Thomas Jefferson, then American Secretary of State, to whom he had applied for a patent, he gives the following short history of his invention: —

“Within about ten days after my first conception of the plan, I made a small, though imperfect, model. Experiments with this encouraged me to make one been improved in the course of the past century in many of its details, but the essential parts are as he left them.”

“The main features consist of a cylinder, generally about four feet long and five inches in diameter, upon which is set a series of circular saws, about half an inch apart, and projecting about two inches above the surface of the revolving cylinder. A mass of cotton in the seed, separated from the cylinder by steel bars or grating, is brought into contact with the numerous teeth on the cylinder. These teeth catch the cotton while playing between the bars, which allow the lint but not the seed to pass. Underneath the saws is a set of stiff brushes on another cylinder revolving in the opposite direction, which brush off from the saw teeth the lint which they have just pulled from the seed. The remaining feature is a revolving fan for producing a current of air to throw the light and downy lint thus liberated to a convenient distance from the revolving saws and brushes.”

Phineas Miller, a Connecticut man and a graduate of Yale, who afterwards married Mrs. Greene, was at this time an inmate of her house, and took a lively interest in the cotton cleaning machine. He formed a partnership with Whitney for the purpose of bringing out the invention, and soon afterwards Whitney went back to Connecticut, where he was to perfect the apparatus, obtain a patent, and manufacture the machines. Before this, rumours of the new apparatus had spread through Georgia and caused great excitement and curiosity. So intense was the desire to see the wonderful invention that before the larger model was finished the building in which it was being constructed was broken open by night and the machine carried off, and before Whitney could obtain a patent many machines were in successful operation, constructed with small deviations from the original, in order to evade legal penalties.

This was the beginning of a long series of troubles and discouragements for Whitney. His workmen became ill, his shop at New Haven, with his machines and papers, was burned, and, worst of all, a report came from England that the manufacturers there condemned the cotton cleaned by his machines on the ground that the staple was greatly injured. These prejudices, however, were happily cleared away, and there arose a great and increasing demand for cotton cleaned by Whitney’s gin; but by this time his patent rights were so encroached upon as to be almost valueless. Numerous lawsuits against infringers were instituted, but it was many years, and after the death of his partner, Mr. Miller, before Whitney could obtain justice. It was on the occasion of the favourable issue of one of these suits in the United States Court, in Georgia, in December, 1807, that Judge Johnson rendered his celebrated decision, in the course of which he said: —

“With regard to the utility of this discovery, the Court would deem it a waste of time to dwell long upon this topic. Is there a man who hears us who has not experienced its utility? The whole interior of the Southern States was languishing, and its inhabitants emigrating for want of some object to engage their attention and employ their industry, when the invention of this machine at once opened views to them, which set the whole country in active motion. From childhood to age it has presented to us a lucrative employment. Individuals who were depressed with poverty and sunk in idleness have suddenly risen to wealth and respectability. Our debts have been paid off. Our capitals have increased, and our lands trebled themselves in value. We cannot express the weight of the obligation which the country owes to this invention. The extent of it cannot now be seen.”

In 1801 the legislature of South Carolina voted to buy the patent rights of Miller & Whitney within that State for fifty thousand dollars, and after some vexatious delays the partners received the money. The next year the State of North Carolina laid a tax, to be continued for five years, upon every cotton

gin working within its borders, and the proceeds, after deducting the expenses of collection, were paid over to the patentee, in return for which he made over his rights to the State. Tennessee likewise passed a law taxing cotton gins for the benefit of the inventor, but the Act was soon suspended.

By the time Whitney had secured a favourable decision in the courts the term of his patent had nearly expired, and though he afterwards, in 1812, made application to the United States Congress for a renewal, his petition was not granted. Taken all in all, his cotton gin brought him great fame, but little fortune, for the money he did derive from the sale of his patent rights was swallowed up in lawsuits and other great expenses.

Feeling uncertain of the financial success of his cotton gin, Whitney devoted himself to a new enterprise in 1798. On January 14 of that year he concluded a contract with the United States Government to furnish ten thousand muskets within a little more than two years. This was a very bold move on Whitney’s part, for this new business had to be built up from the very foundations. He had to borrow capital, erect a factory, make tools, gather his raw materials together, and instruct his workmen. Moreover, he was himself inexperienced in this branch of manufacture. But his ingenuity, good sense, pluck, and perseverance carried him over all obstacles; and though, owing to unforeseen difficulties, he had to get an extension of time, his contract was fulfilled to the entire satisfaction of the government.

His business being now firmly established, he was able to undertake new contracts for arms with the United States and the State of New York with profit to all parties concerned. It may be interesting to record some remarks on Whitney’s methods of manufacture by a gentleman who was personally and intimately acquainted with the subject: —

” The several parts of the musket were, under this system, carried along through the various processes of manufacture, in lots of some hundreds or thousands of each. In their various stages of progress they were made to undergo successive operations by machinery, which not only vastly abridged the labour, but at the same time so fixed and determined their form and dimensions as to make comparatively little skill necessary in the manual operations. Such were the construction and arrangement of this machinery that it could be worked by people of little or no experience, and yet it performed the work with so much precision that when, in the later stages of the process, the several parts of the musket came to be put together, they were as readily adapted to one another as if each had been made for its respective fellow. A lot of these parts passed through the hands of several different workmen successively (and in some cases returned several times, at intervals more or less remote, to the hands of the same workman), each performing upon them every time some single and simple operation, by machinery or by hand, until they were completed.”

“Thus Mr. Whitney reduced a complex business, embracing many ramifications, almost to a mere succession of simple processes, and was thereby enabled to make a division of the labour among his workmen, on a principle which was not only more extensive, but also altogether more philosophical than that pursued in the English method. In England, the labour of making a musket was divided by making the different workmen the manufacturers of different limbs, while in Mr. Whitney’s system the work was divided with reference to its nature, and several workmen performed different operations on the same limb.”

“When Mr. Whitney’s mode of conducting the business was brought into successful operation, and the utility of his machinery was fully demonstrated, the clouds of prejudice which lowered over his first efforts were soon dissipated, and he had the satisfaction of seeing not only his system, but most of his machinery, introduced into every other considerable establishment for the manufacture of arms, both public and private, in the United States.”

These labours of Whitney were of the greatest value to the public interest. A former Secretary of War of the United States admitted, in a conversation with the inventor, that the United States Government was saving twenty-five thousand dollars a year at the two public armories alone, by his improvements, and this estimate is believed to be far below the true one.

Nor was the utility of Whitney’s labours limited to the particular business in which he was engaged. Many of the inventions which he made to facilitate the manufacture of muskets, were applicable to most other manufactures of iron and steel. To many of these they were soon extended and became the nucleus around which other inventions clustered. And at the present day Whitney’s beneficent influence may be recognised in nearly every factory and machine shop in the United States.

It was characteristic of Whitney’s ingenuity and humane disposition that his attention was directed even to the mangers for his cattle, and to their fastenings. It is said that the latter were so contrived that, by means of a small weight at the end of the halter, the animal could always move his head with facility, but could not draw out the rope so as to become entangled in it, nor could he easily waste his hay.

The domestic arrangements of Whitney’s house also bore testimony to the ingenuity which he showed in common things, as well as in those more important. The several drawers of his bureaus, for instance, were locked by a single movement of one key, of a peculiar construction, and an attempt to open any drawer except one would prove ineffectual, even with the right key, which, however, being applied in the proper place, threw all the bolts at one movement.

He was a pioneer in another field which is just beginning to be properly cultivated. His factory was situated near New Haven, on the banks of a little river, and, not satisfied with utilitarian perfection alone in his shops, he devoted his attention also to their aesthetic side, and made them and the neighbouring cottages of his workmen harmonious parts of a picturesque landscape.

In person, Mr. Whitney is said to have been considerably above the ordinary size, of dignified carriage, and of an open, manly and agreeable countenance. He was a man of broad culture, interested in all the great questions of the day. The advantage of a liberal education to a man of mechanical invention was very conspicuous in his case, for his college training not only fitted him to rationally enjoy his moments of leisure, but it helped directly to guide his inventive faculty and to lead him to the highest success in his life work.

He had an extensive acquaintance among the leading men of his time, and was universally esteemed. He took great pleasure in the society of his friends, and he was a great favourite with children.

Happy in his home and his family relations, his latter years were blessed with well-earned prosperity. After a lingering and painful illness, borne with great fortitude and resignation, he died on the 8th of January, 1825.