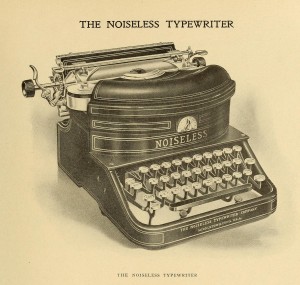

The Noiseless Typewriter circa 1910

More than six years ago there was a brief note published in this magazine, calling attention to the desirability of producing a mechanical writing machine which should be free from the noise and clatter usually considered inherent in such machines. Speaking editorially, we said:

“A noiseless typewriter is something devoutly to be hoped for. The clatter of the average machine ought to have been a fruitful stimulus to inventors long ago, but typewriter ingenuities seem to have followed other lines than that of producing noiseless working, so that the production is still an open one. Not only is the continual din of the machine nerve-straining to others than the operator, but from an engineering standpoint it means wear and tear of mechanism and misspent energy — imperfect design and construction — which thoughtful design and construction ought to overcome to a measurable degree.”

During the interval which has elapsed since this call was issued to inventors and mechanicians, the seed thus sown has sprouted and attained full fruition, and to-day the noiseless typewriter is an accomplished fact.

The early attempts to reduce the noise of typewriting machines were directed principally towards the absorption of the noise after it had been produced, and such appliances as clamps, rubber feet, special pads, platens and the like, demonstrated the desire of manufacturers to meet the demand for less noise. All such remedies, however, were of little avail, since the fundamental action of the machines, consisting of a succession of sharp hammer blows upon a firm platen necessarily involved such a penetrating noise as to be incapable of concealment by any such palliatives.

The real remedy lay deeper in the construction of the machine, in the design of an action which should not produce noise at all, and it is this most desirable result which has been achieved by the engineers and inventors who have been working upon the problem for the past seven years.

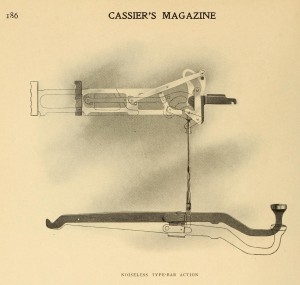

Since the principal cause of the noise produced by the ordinary typewriting machines is produced by the pounding of the type-bars upon the platen or roller, it became evident that this method of action should be modified. The result has been the substitution, in the noiseless typewriter, of pressure instead of blows, to make the impression upon the paper. While this removed the principal source of the noise, there were other contributing elements to the general clatter of the older machines, and in the new machine these are wholly removed by the use of noiseless ratchets, in which the pawls are lifted clear of the teeth, for the earlier devices which produced the nerve-rasping sounds so familiar in the busy office.The employment of ball bearings in all places where their use will minimize friction and prevent wear and noise is an essential element in noiseless construction. The escapement is designed so as to obviate noise without interfering with speed and reliability and thus all disturbing sounds are prevented, obviating any useless attempts at smothering noise.

The general arrangement of the machine is clearly shown in the illustration. The type-bars are arranged in a semi-circle, radiating to the printing point, and their motion is horizontal, pushing the type against the paper and platen by a combination of toggle and cam, which gives an increasing pressure at the moment of contact, similar to that long since recognized in every printing office as the correct method of obtaining the best effect. The type-bars are of a form permitting accurate guidance and maximum stiffness, the type itself being riveted firmly to the end.

Each type-bar unit is capable of individual adjustment, so that the impression may be regulated according to the area of surface, permitting entire control of the pressure upon the small punctuation marks, as well as upon the full-faced capitals. A general adjustment of the carriage enables the whole pressure to be regulated according to the number of sheets used, as in case of manifolding. The adoption of the pressure principle enables a firm steel platen to be used behind the paper instead of requiring the rubber roller to receive the blows of the type, thus giving especially good results in manifolding and prolonging the life of the roller and ribbon.

At the moment of printing, the type-bar is locked at top, bottom and sides, as shown in the illustration, so that perfect alignment is secured and maintained at all times.

In order to obtain perfect assurance that the machine will not become noisy after continual use, the noiseless typewriter has been tested under power at a rate corresponding to seven years of constant and severe service without revealing appreciable wear or noise.

It is only after long years of experiment, test and investigation that this notable machine has been permitted to be shown and offered, but the demonstrations of its satisfactory performance and of its full right to the claim of the title of “noiseless” have been so convincing that it is now placed upon the market.

The works of the Noiseless Typewriter Company are at Middletown, Conn., and its main offices at 320 Broadway, New York City.